Image 1 of 12

Image 1 of 12

Image 2 of 12

Image 2 of 12

Image 3 of 12

Image 3 of 12

Image 4 of 12

Image 4 of 12

Image 5 of 12

Image 5 of 12

Image 6 of 12

Image 6 of 12

Image 7 of 12

Image 7 of 12

Image 8 of 12

Image 8 of 12

Image 9 of 12

Image 9 of 12

Image 10 of 12

Image 10 of 12

Image 11 of 12

Image 11 of 12

Image 12 of 12

Image 12 of 12

Frontier SB2164, SB2176 UHMW Wear Bar and UHMW Shoes

Replaces the Following Deere Part Numbers

Wear Bar 5RD669305 (2164 model Hydraulic Blower)

Wear Bar 5RD669136 (2176 model Hydraulic Blower)

Steel Shoes 5RD666254, 5RD666255

End the pavement surface grinding and damage of the steel wear bar and steel shoes on the Frontier / Deere SB2164 and SB2176 Front Mounted snowblower.

Please note, the Frontier SB2164 / SB2174 blowers have some serial number variations on the parts, depending upon when the blower was assembled. The distinctions are based upon these blower serial numbers

Serial Numbers up to <100057

Serial Numbers #100058>

As a result, we verify the specific dimensions of these blowers wear bar before we custom machine these wear bars out of UHMW to improve your snow blowers performance and function while replacing the steel wear bar.

The custom made UHMW wear bars include all corrosion resistant hardware to install on your blower.

We also offer the UHMW blower shoes if your blower uses the bolt on steel shoes with the part numbers listed above. The UHMW shoes are sold as a pair and also include all hardware to install.

Benefits of replacing the steel wear bar and shoes with our UHMW wear bar and shoe set include;

Stops the steel wear bar abrasion on the pavement which causes surface damage.

Ends the grinding and scraping noise of the blower on the pavement.

Protects the blower and the pavement from surface friction and wear damage.

No more rust on the floor, rust on the pavement and scraped off pavement surface sealers, garage floor paint and other other surface protection.

Makes the blower slide with far less friction, less noise, less wear on the steel and the pavement and less wear on the blower assembly.

Since the blowers slides much easier, it requires less power to push, allows lower engine RPM’s and can reduce tractor drive train stress and wear.

Some tractor owners report their machines push the blower so much better, they don’t need tire chains or other traction aids. This also reduces pavement wear as well as tractor and implement wear and tear.

We offer just what you want to buy to stop the pavement damage and protect your pavement from blower surface friction and wear.

A special Message about ordering these parts-

The SB1264 and SB1276 front mounted hydraulic driven snowblowers are a unique blower has a serial number break in the units production. which is less common than many Deere and Frontier Blowers. As a result, we produce these parts for your blower when ordered.

We will need to confirm some dimensions on your blower wear bar.

These dimensions can be obtained with a tape measure or similar.

Serial number variations in these blowers demand we confirm your wear bar is made perfectly to fit your blower.

As a result, please allow 12 to 15 business days (M-F, excluding weekends, holidays, etc) from your confirmation of the blowers dimensions, for your order to be produced and shipped. These parts are expensive to produce and ship and we want to make sure you order is perfect for your machine. Thanks for your understanding on this important matter.

The photos are stock pictures of general UHMW wear bars and UHMW shoes. These are not the UHMW wear bar or UHMW shoes for this front mounted hydraulic blower. Actual photos of the parts when produced, will be added to this listing. Thanks for your understanding until actual parts for these blowers will be produced.

Product Ordering Options

You can order any of the following for the Frontier / Deere SB2164 or SB2176 front mounted blowers;

One UHMW wear bar custom machined to fit your blower, or

One Pair of UHMW custom made blower shoes to replace the steel shoes

or a “Pavement Protection Pkg”, which is the UHMW wear bar and a pair of UHMW shoes and all hardware to install, for your blower. The Pavement Protection Pkg saves you 10% over buying the wear bar and shoes separately.

These are custom made, Direct Bolt on replacement parts just for these blower models. These parts Install with basic hand tools.

Ordering, How to order and What your order will include

Please always follow these steps when ordering parts for your blower

Confirm your blower model is either the SB 1264 or SB 1276 Front Mounted, Hydraulic driven snowblower. Check the model tag to confirm.

If there are serial number breaks in the model, make sure you know the serial number of your blower by taking a photo of the production tag on the blower.

Select the specific blower model on our site, either the SB1264 or SB1276.

Select the items you wish to purchase, either the UHMW wear bar, the UHMW blower shoes pair or the Pavement Protection Package of the UHMW wear bar and UHMW shoes combined.

Input your name, address and contact information and select your payment method.

Make sure if you have any questions, you contact us so we can assist you. Thank you for your interest in our products.

Order just what you want and save money when ordering the Pavement Protection Package, which includes the UHMW Wear bar, a Pair of UHMW blower shoes and the hardware to install as well as installation and use instructions.

Common Questions and Answers

Q.1-Why do so many blower owners want to replace their blowers steel wear bar, steel shoes and switch to the UHMW material?

A. 1.- The steel wear edge and shoes damage the concrete and asphalt with each use. This leads to

costly pavement repairs

shortens the useful life of the pavement.

premature pavement repairs and replacement.

reduces the appeal and value of your property.

Q. 2.- Why is UHMW the best product to replace the steel wear edge and shoes on the snow blowers, snow plows and snow pushers?

A.2. - UHMW is Ultra High Molecular Weight Polyethylene , which is the most wear resistant plastic composite material produced.

It is designed to be low friction and very durable

UHMW is the most wear resistant and strongest plastic based product in the world.

Q. 3.- How does the UHMW compare to mild steel which is often used on these blower shoes, wear bars, etc. in terms of durability, length of wear before needing to be replaced, etc?

A. 3.- To help extend our products wear life and delay its replacement,

Our UHMW products are designed and produced to be thicker and wider than the steel they replace.

Our parts are made specifically for each application to achieve the longest useful life, often for several seasons.

Of course, someone clearing a driveway which is a mile long will need to replace the wear bar sooner than someone who clears a driveway which is 400’ long.

Q.4.- What do you mean when you say your blower wear bars or your blower shoes are “Double Sided” or that they can be “inverted or reversed?”

A. 4.- We make our UHMW shoes to be double sided, so you can install the shoes, use them, adjust them as needed as they wear. When the first side is worn, unbolt the shoes, flip them over and put them back on the blower and start again. Its like getting two complete sets of shoes in each set of shoes you purchase.

Q.5.- Why would SBS, LLC make the blower shoes and many of the blower wear bars to be “Double Sided”? Doesn’t it make the shoes more costly?

A. 5.- We like to provide products which exceed our customers expectations. We are always seeking the “Best Solution”, not the cheapest and easiest way to do something. Using creative thinking, reducing wasted materials and using our production as efficiently as possible, allows us to produce shoes and wear bars that work great, last a long time and also stop the pavement friction and damage.

Q.6.- Why aren’t the snow blowers, blades and pushers made with these UHMW parts instead of steel, on their new machines?

A. 6.- Simple, it money. The UHMW material cost between 10x to 20x the cost of the steel it replaces. The higher the cost of the parts, the higher the selling price of the blower, blade or snow pusher.

Plus, companies who make the blowers, blades and snow pushers sell the wear parts and replacement parts. Their objective is to keep the price of the plow, blade or blower low and to sell replacement wear parts to their customers.

How our UHMW Wear Bars and UHMW Shoes are saving customers money.

Homeowners, Property Managers, Home Owners Associations and Commercial Property Investors are among those who are learning that the small investment to prevent surface friction and wear on their pavement when clearing snow and ice, is a very wise investment providing a great return.

When the pavement and the snow clearing implement both experience lower surface friction, these are the proven results of this lower friction contact.

The pavement surface experiences less wear, which means it delays the period between surface sealing on asphalt and concrete often by as much as 3 years.

The less wear means better surface integrity, which means fewer cracks and places for water to penetrate the surface.

Better surface integrity prevents moisture from penetrating the surface and resulting in fewer freeze / thaw cycles which damage the pavement.

When the pavement is smoother, its easier to maintain and safer for pedestrians, bicycles, motorcycle traffic and all who use the surface.

The lower friction clearing action avoids displacing previous pavement repairs.

This avoids duplicate pavement repair expense while also prolongs the future surface repairs.

Less friction on the blower, blade or pusher extends its useful life and delays wear edge and shoe part replacement and repairs.

When the implement is easier to push, the machine pushing the implement experiences improved traction. This means less tire spin, less surface friction between the tires and the pavement and less need for any traction aids like tire chains, Terra grips, etc.

Less tire spin, means more traction which means less time spent clearing snow, This extends tractor tire life since there is lower pavement surface friction. This saves tractor fuel, operator time, machine wear and tear and of course, pavement damage.

Its a win for all involved looking to reduce costs, prolong pavement life, keep the pavement and property visually appealing, extend machine and implement useful life and use less fuel, make less noise, reduce pavement clearing time and the list seems to go on and on…..

All of these benefits from the small investment made in the upgraded UHMW wear edges and shoes for snow blowers, snow plows, snow pushers, etc.. It’s no wonder those who switch to our low friction rubber and or UHMW wear bars and shoes never want to go back to their steel wear edges and shoes again……

The most common remark we hear from customers is “I wish I had switched to these UHMW Wear bars (or rubber wear edge) and UHMW Shoes long, long ago”…….

Thank you for your interest in our Products. Please contact us with any questions or concerns you may have.

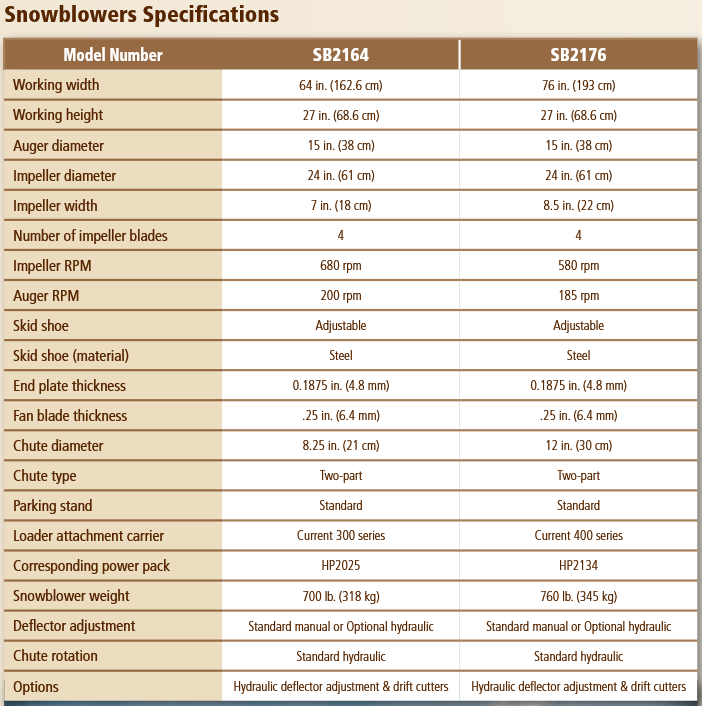

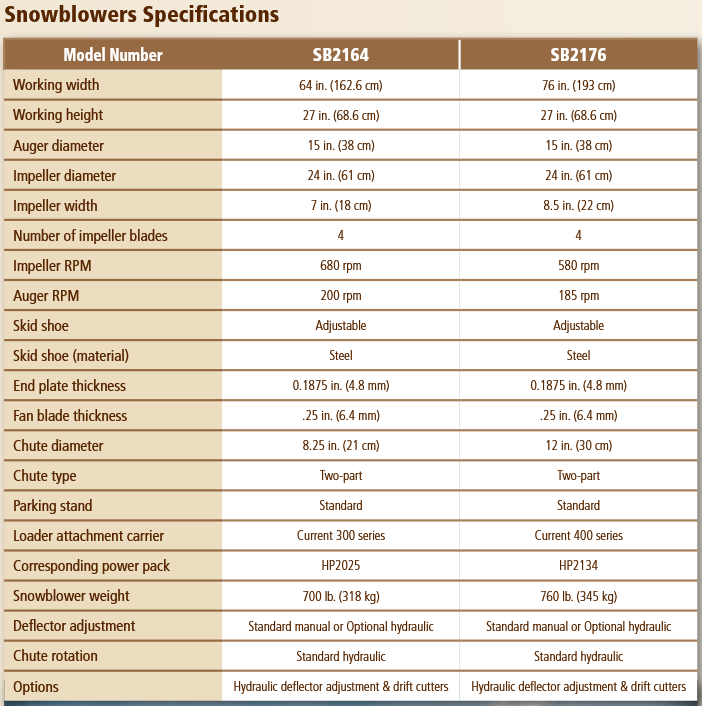

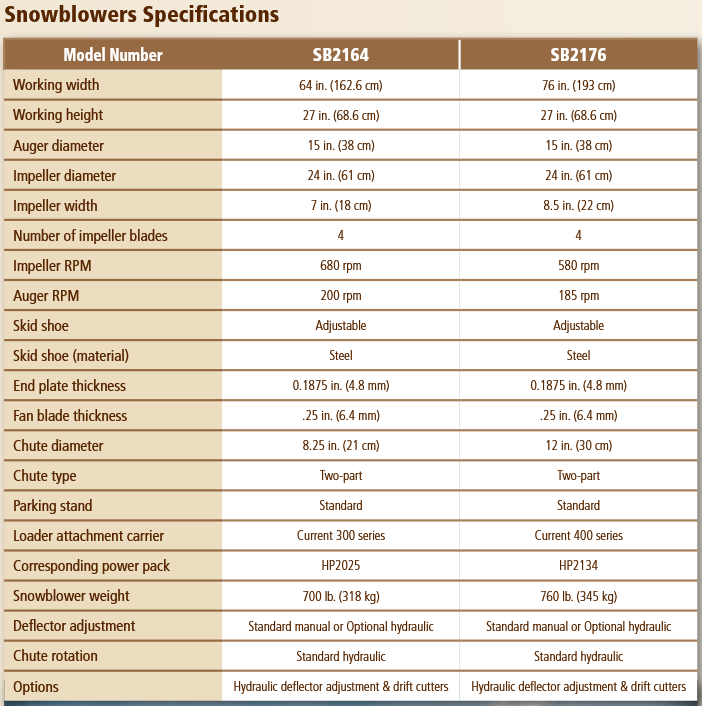

Images of the blower and hydraulic power pack are from Deere / Frontier 300 and 400 Series Loader Mount Attachment Brochure. Images are for identification of the blower series. All copyrights, patents, etc are property of John Deere and Frontier Implements.

Replaces the Following Deere Part Numbers

Wear Bar 5RD669305 (2164 model Hydraulic Blower)

Wear Bar 5RD669136 (2176 model Hydraulic Blower)

Steel Shoes 5RD666254, 5RD666255

End the pavement surface grinding and damage of the steel wear bar and steel shoes on the Frontier / Deere SB2164 and SB2176 Front Mounted snowblower.

Please note, the Frontier SB2164 / SB2174 blowers have some serial number variations on the parts, depending upon when the blower was assembled. The distinctions are based upon these blower serial numbers

Serial Numbers up to <100057

Serial Numbers #100058>

As a result, we verify the specific dimensions of these blowers wear bar before we custom machine these wear bars out of UHMW to improve your snow blowers performance and function while replacing the steel wear bar.

The custom made UHMW wear bars include all corrosion resistant hardware to install on your blower.

We also offer the UHMW blower shoes if your blower uses the bolt on steel shoes with the part numbers listed above. The UHMW shoes are sold as a pair and also include all hardware to install.

Benefits of replacing the steel wear bar and shoes with our UHMW wear bar and shoe set include;

Stops the steel wear bar abrasion on the pavement which causes surface damage.

Ends the grinding and scraping noise of the blower on the pavement.

Protects the blower and the pavement from surface friction and wear damage.

No more rust on the floor, rust on the pavement and scraped off pavement surface sealers, garage floor paint and other other surface protection.

Makes the blower slide with far less friction, less noise, less wear on the steel and the pavement and less wear on the blower assembly.

Since the blowers slides much easier, it requires less power to push, allows lower engine RPM’s and can reduce tractor drive train stress and wear.

Some tractor owners report their machines push the blower so much better, they don’t need tire chains or other traction aids. This also reduces pavement wear as well as tractor and implement wear and tear.

We offer just what you want to buy to stop the pavement damage and protect your pavement from blower surface friction and wear.

A special Message about ordering these parts-

The SB1264 and SB1276 front mounted hydraulic driven snowblowers are a unique blower has a serial number break in the units production. which is less common than many Deere and Frontier Blowers. As a result, we produce these parts for your blower when ordered.

We will need to confirm some dimensions on your blower wear bar.

These dimensions can be obtained with a tape measure or similar.

Serial number variations in these blowers demand we confirm your wear bar is made perfectly to fit your blower.

As a result, please allow 12 to 15 business days (M-F, excluding weekends, holidays, etc) from your confirmation of the blowers dimensions, for your order to be produced and shipped. These parts are expensive to produce and ship and we want to make sure you order is perfect for your machine. Thanks for your understanding on this important matter.

The photos are stock pictures of general UHMW wear bars and UHMW shoes. These are not the UHMW wear bar or UHMW shoes for this front mounted hydraulic blower. Actual photos of the parts when produced, will be added to this listing. Thanks for your understanding until actual parts for these blowers will be produced.

Product Ordering Options

You can order any of the following for the Frontier / Deere SB2164 or SB2176 front mounted blowers;

One UHMW wear bar custom machined to fit your blower, or

One Pair of UHMW custom made blower shoes to replace the steel shoes

or a “Pavement Protection Pkg”, which is the UHMW wear bar and a pair of UHMW shoes and all hardware to install, for your blower. The Pavement Protection Pkg saves you 10% over buying the wear bar and shoes separately.

These are custom made, Direct Bolt on replacement parts just for these blower models. These parts Install with basic hand tools.

Ordering, How to order and What your order will include

Please always follow these steps when ordering parts for your blower

Confirm your blower model is either the SB 1264 or SB 1276 Front Mounted, Hydraulic driven snowblower. Check the model tag to confirm.

If there are serial number breaks in the model, make sure you know the serial number of your blower by taking a photo of the production tag on the blower.

Select the specific blower model on our site, either the SB1264 or SB1276.

Select the items you wish to purchase, either the UHMW wear bar, the UHMW blower shoes pair or the Pavement Protection Package of the UHMW wear bar and UHMW shoes combined.

Input your name, address and contact information and select your payment method.

Make sure if you have any questions, you contact us so we can assist you. Thank you for your interest in our products.

Order just what you want and save money when ordering the Pavement Protection Package, which includes the UHMW Wear bar, a Pair of UHMW blower shoes and the hardware to install as well as installation and use instructions.

Common Questions and Answers

Q.1-Why do so many blower owners want to replace their blowers steel wear bar, steel shoes and switch to the UHMW material?

A. 1.- The steel wear edge and shoes damage the concrete and asphalt with each use. This leads to

costly pavement repairs

shortens the useful life of the pavement.

premature pavement repairs and replacement.

reduces the appeal and value of your property.

Q. 2.- Why is UHMW the best product to replace the steel wear edge and shoes on the snow blowers, snow plows and snow pushers?

A.2. - UHMW is Ultra High Molecular Weight Polyethylene , which is the most wear resistant plastic composite material produced.

It is designed to be low friction and very durable

UHMW is the most wear resistant and strongest plastic based product in the world.

Q. 3.- How does the UHMW compare to mild steel which is often used on these blower shoes, wear bars, etc. in terms of durability, length of wear before needing to be replaced, etc?

A. 3.- To help extend our products wear life and delay its replacement,

Our UHMW products are designed and produced to be thicker and wider than the steel they replace.

Our parts are made specifically for each application to achieve the longest useful life, often for several seasons.

Of course, someone clearing a driveway which is a mile long will need to replace the wear bar sooner than someone who clears a driveway which is 400’ long.

Q.4.- What do you mean when you say your blower wear bars or your blower shoes are “Double Sided” or that they can be “inverted or reversed?”

A. 4.- We make our UHMW shoes to be double sided, so you can install the shoes, use them, adjust them as needed as they wear. When the first side is worn, unbolt the shoes, flip them over and put them back on the blower and start again. Its like getting two complete sets of shoes in each set of shoes you purchase.

Q.5.- Why would SBS, LLC make the blower shoes and many of the blower wear bars to be “Double Sided”? Doesn’t it make the shoes more costly?

A. 5.- We like to provide products which exceed our customers expectations. We are always seeking the “Best Solution”, not the cheapest and easiest way to do something. Using creative thinking, reducing wasted materials and using our production as efficiently as possible, allows us to produce shoes and wear bars that work great, last a long time and also stop the pavement friction and damage.

Q.6.- Why aren’t the snow blowers, blades and pushers made with these UHMW parts instead of steel, on their new machines?

A. 6.- Simple, it money. The UHMW material cost between 10x to 20x the cost of the steel it replaces. The higher the cost of the parts, the higher the selling price of the blower, blade or snow pusher.

Plus, companies who make the blowers, blades and snow pushers sell the wear parts and replacement parts. Their objective is to keep the price of the plow, blade or blower low and to sell replacement wear parts to their customers.

How our UHMW Wear Bars and UHMW Shoes are saving customers money.

Homeowners, Property Managers, Home Owners Associations and Commercial Property Investors are among those who are learning that the small investment to prevent surface friction and wear on their pavement when clearing snow and ice, is a very wise investment providing a great return.

When the pavement and the snow clearing implement both experience lower surface friction, these are the proven results of this lower friction contact.

The pavement surface experiences less wear, which means it delays the period between surface sealing on asphalt and concrete often by as much as 3 years.

The less wear means better surface integrity, which means fewer cracks and places for water to penetrate the surface.

Better surface integrity prevents moisture from penetrating the surface and resulting in fewer freeze / thaw cycles which damage the pavement.

When the pavement is smoother, its easier to maintain and safer for pedestrians, bicycles, motorcycle traffic and all who use the surface.

The lower friction clearing action avoids displacing previous pavement repairs.

This avoids duplicate pavement repair expense while also prolongs the future surface repairs.

Less friction on the blower, blade or pusher extends its useful life and delays wear edge and shoe part replacement and repairs.

When the implement is easier to push, the machine pushing the implement experiences improved traction. This means less tire spin, less surface friction between the tires and the pavement and less need for any traction aids like tire chains, Terra grips, etc.

Less tire spin, means more traction which means less time spent clearing snow, This extends tractor tire life since there is lower pavement surface friction. This saves tractor fuel, operator time, machine wear and tear and of course, pavement damage.

Its a win for all involved looking to reduce costs, prolong pavement life, keep the pavement and property visually appealing, extend machine and implement useful life and use less fuel, make less noise, reduce pavement clearing time and the list seems to go on and on…..

All of these benefits from the small investment made in the upgraded UHMW wear edges and shoes for snow blowers, snow plows, snow pushers, etc.. It’s no wonder those who switch to our low friction rubber and or UHMW wear bars and shoes never want to go back to their steel wear edges and shoes again……

The most common remark we hear from customers is “I wish I had switched to these UHMW Wear bars (or rubber wear edge) and UHMW Shoes long, long ago”…….

Thank you for your interest in our Products. Please contact us with any questions or concerns you may have.

Images of the blower and hydraulic power pack are from Deere / Frontier 300 and 400 Series Loader Mount Attachment Brochure. Images are for identification of the blower series. All copyrights, patents, etc are property of John Deere and Frontier Implements.