Image 1 of 10

Image 1 of 10

Image 2 of 10

Image 2 of 10

Image 3 of 10

Image 3 of 10

Image 4 of 10

Image 4 of 10

Image 5 of 10

Image 5 of 10

Image 6 of 10

Image 6 of 10

Image 7 of 10

Image 7 of 10

Image 8 of 10

Image 8 of 10

Image 9 of 10

Image 9 of 10

Image 10 of 10

Image 10 of 10

John Deere 54" Standard Duty Front Plow Rubber Edge/Kit to replace M42868

This kit includes FREE shipping, via USPS or UPS Ground Delivery in the Lower 48 States

Custom made to fit the Deere 54” front Snow Plow, this edge replaces the steel edge on the plow with our Standard Duty plow rubber edge. The rubber edge will protect your pavement from the surface abrasion and scraping damage from the steel edge which comes on the plow when purchased new.

How to order this product

54 Inch Deere Front Plow

Decide whether you want to order the Standard Duty Rubber Edge Only or the Standard Duty Rubber Edge Kit.

If you have a 54” Deere plow and have the steel strap edge on the plow, you can order just the rubber edge and it will ship with a complete set of corrosion resistant hardware. As long as you have the 54” plow steel plow strap, you can save some money and use that strap on the 54” plow new rubber plow edge.

If you prefer all new components, or your steel plow strap is missing or damaged, order the Standard Duty Rubber Edge KIT for everything you need to install this on your plow and replace the steel plow edge.

Who are the Standard Duty Rubber Plow Edge/ Kit Customers?

Those owners who want to stop the pavement surface abrasion and switch to a rubber edge to protect the pavement surface.

The owner who wants a professionally designed and machined rubber edge kit which will bolt directly onto the plow and provide years of reliable use.

Those owners who don’t want a project where they have to modify and alter materials to make them fit.

Those owners who want to stop the plow banging on the pavement and the steel plow edge striking pavement expansion joints, etc.

Those owners who are tired of tearing up the yard and lawn or grass areas with the steel plow edge.

If your plow blade “trips” often while plowing, our rubber edge will dramatically reduce these plow tripping events by allowing the plow to clear the raised sections and edges more easily.

Contents of the Standard Duty Plow Edges and the Standard Duty Plow Edge Kits for the 54” and 60” Deere front plows

Deere 54” Front Plow

The Standard Duty Rubber Plow Edge includes

(1) 4” x 1/2” fully machined rubber edge

Full Set of corrosion resistant hardware set to install the new rubber edges

The Standard Duty Rubber Plow Edge KIT includes

(1) 4” x 1/2” fully machined rubber edge

the custom made UHMW Mounting strap to secure the rubber edges..

Full Set of corrosion resistant hardware set to install the new rubber edges

Our Rubber Edge Kit is the parts and pieces to transition the plow from its steel edge to the rubber edge kit.

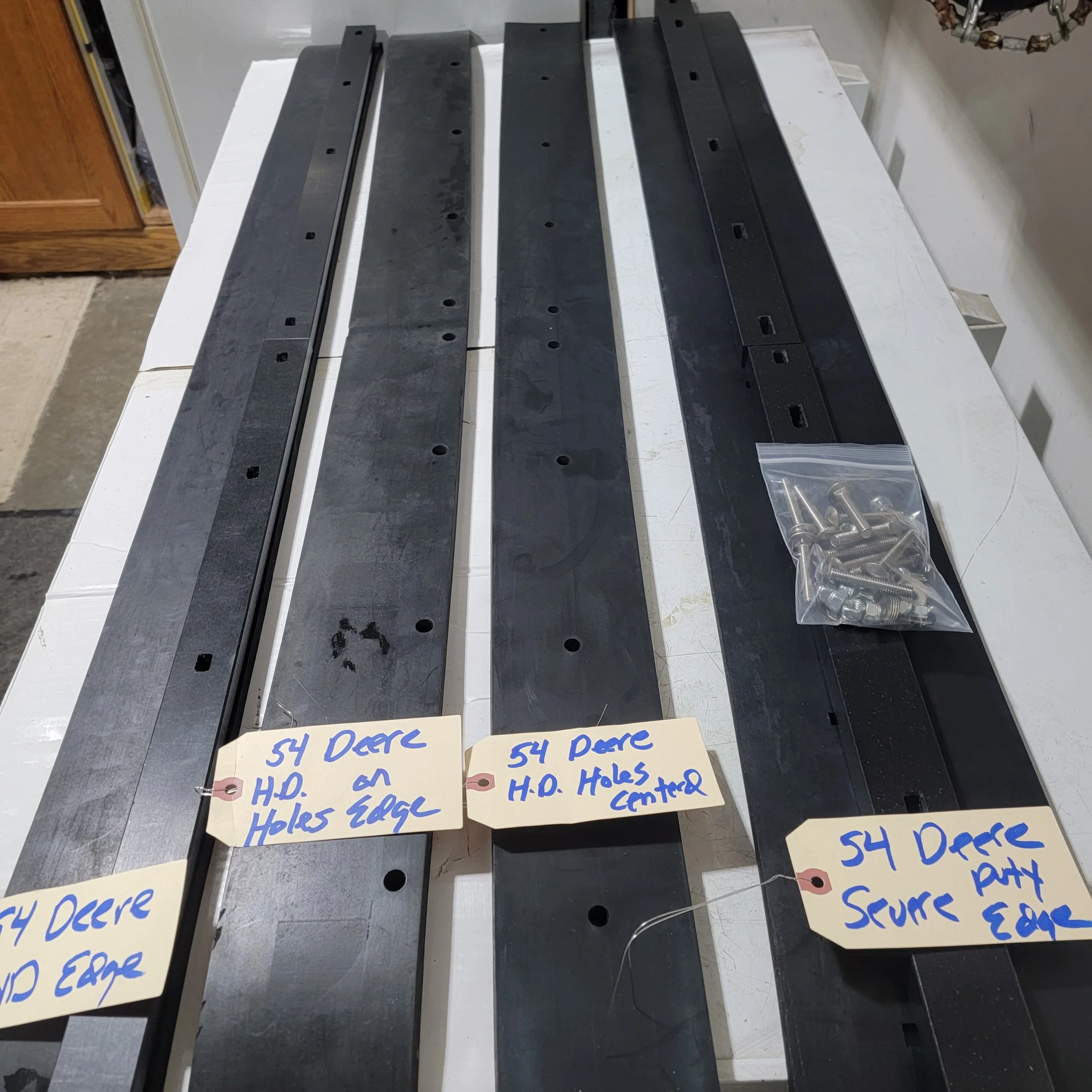

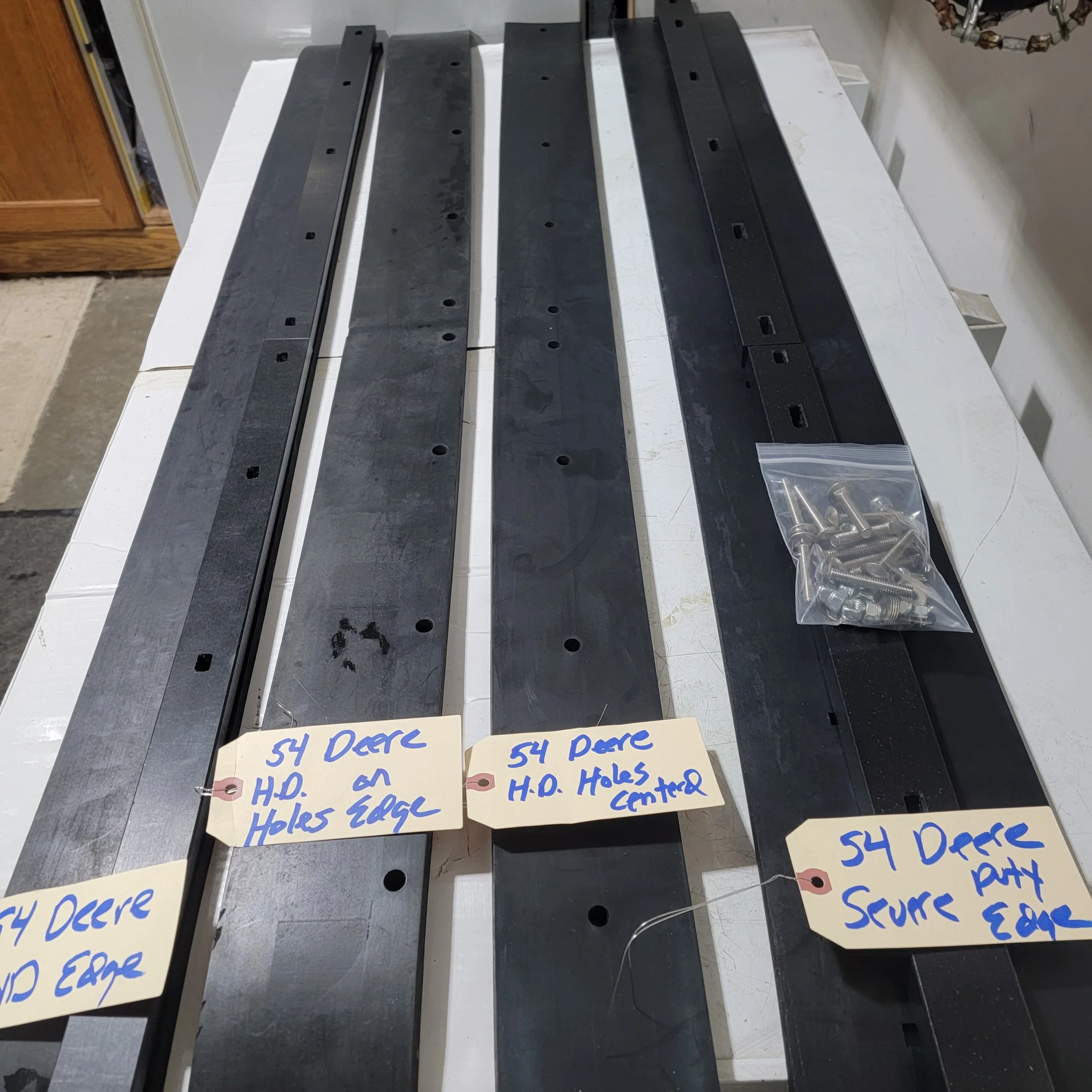

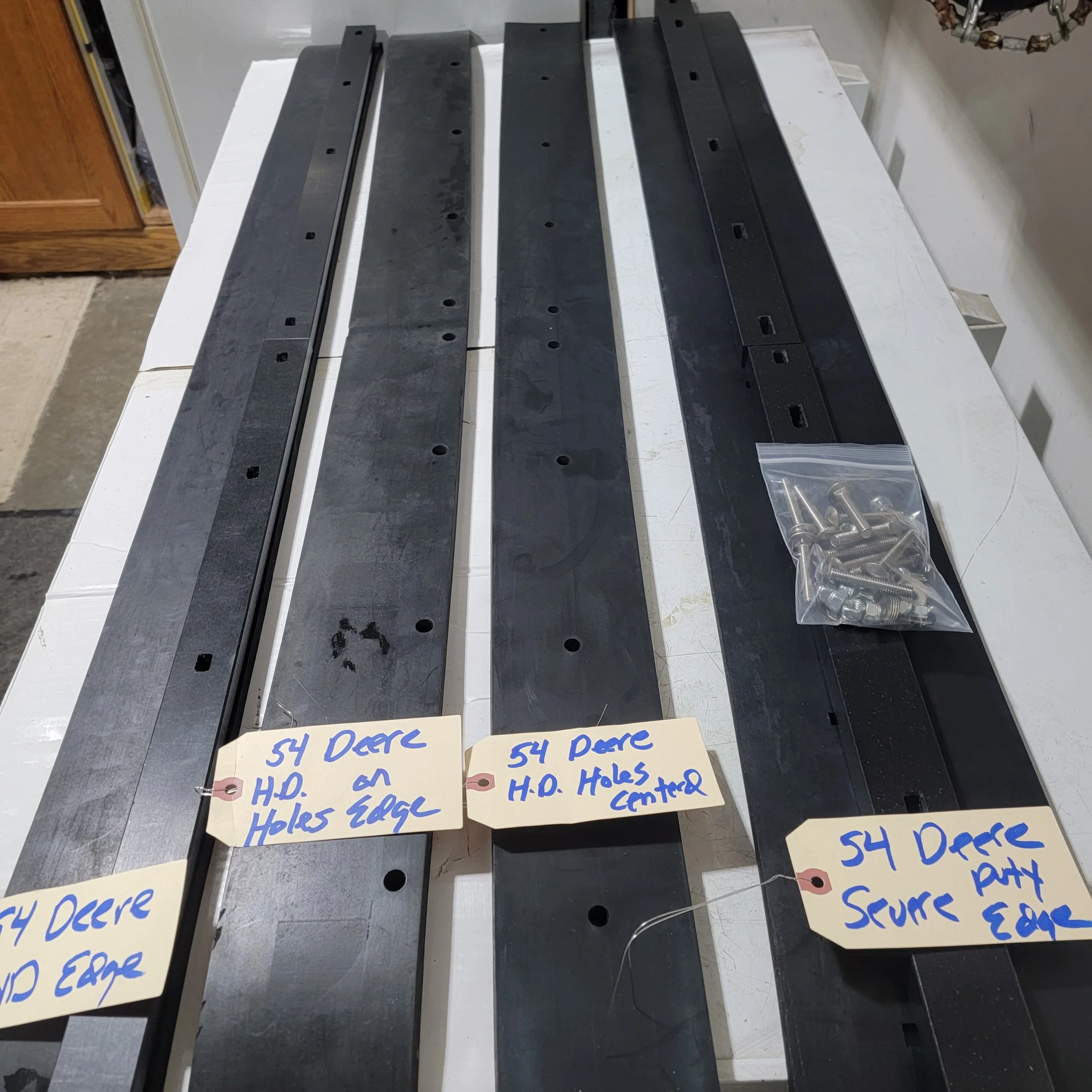

Center Cut Holes or Top Edge Cut Holes

on the 54” Plow Rubber Edge

Mounting holes are available along the top edge of the 54” rubber edge or down the center of the 54” rubber edge. Here is the difference and the advantages of either option.

Center Cut Holes in the 54” edge requires the use of our UHMW mounting strap to install this on your plow.

Center Cut Holes are for the rubber edges sold in our Center Cut 54” Rubber Plow edge Kits. By machining the mounting holes down the center of the 4” tall rubber edge, our UHMW mounting strap and hardware provide you with a “Double Sided Wear Edge” for the standard rubber edge.

Benefits of ordering the center cut holes includes

Ability to have two wear edges on the rubber material. Each side would have 1.25” of rubber edge beneath the plow blade.

When the rubber edge wears on one side, flip the rubber edge over and start with the other wear side.

Provides a total of 2.5” of rubber wear out of the edge, using 1.25” of rubber on each side of the edge.

Having 1.25” of the 1/2” standard duty rubber edge makes the rubber flexible enough to protect the pavement from abrasion, but the rubber edge is still stiff enough to scrape snow from the surface which might be hard packed from being driven over.

Please note, in order to use the 54” rubber edge with the holes down the center, you MUST order our 54” rubber Plow edge KIT which includes our UHMW mounting strap machined to mount the edge and our hardware package to install the rubber edge and the UHMW strap on your plow.

The steel plow edge on the 54” Deere can NOT be used for the Center Cut rubber plow edge as the steel strap is too wide to mount the rubber with the holes down the center of the rubber edge.

Top Edge Hole Location on the 54” Deere Plow Rubber Edge.

You can select our rubber plow edge for the 54’ Plow with the mounting holes along the top edge of the rubber. You can use the 54” plow steel strap to mount the 54” Standard Duty Rubber Edge with the holes cut into the rubber along the top edge. This rubber edge can also be installed as part of our “Kit” with the Standard Duty Rubber Edge and the UHMW Mounting kit and hardware.

Advantages of ordering the 54” Rubber Plow Edge with holes cut into the rubber along the top edge of the rubber include;

The standard duty rubber edge can be installed with the steel plow edge strap (following specific installation instructions) which might be on your plow.

Using the top cut hole location makes the rubber edge amount below the steel strap about 2.5” with about 2” of that distance below the bottom of the plow.

Standard Duty Rubber Edge

or

Standard Duty Rubber Edge Kit

We offer the “Rubber Only” and the “Rubber Edge Kit”.

The “Rubber Only” is intended to be a replacement rubber edge for those who have been using our rubber edge kit and need to replace it. Please do NOT order the Rubber ONLY option with the center cut holes if you do not have our UHMW mounting strap kit. The rubber edge can not be mounted using the steel strap when the holes are cut down the center as the steel strap does not provide the clearance for holes with

The “Rubber Edge Kits” are for those owners who are removing the plows steel edge and desire to upgrade their plow to a professionally machined rubber edge plow kit on the market.

How our Rubber edge is Superior to the Deere rubber edge sold under part number M42868

The Deere rubber squeegee sold under M42868 is 3” tall and just under 1/2” thick.

Our Standard rubber squeegee is 4” tall, 1/2” thick and weighs 34% more than the Deere rubber edge

Our Standard Rubber edge ships with either center cut or top edge cut holes already in the rubber and ready to mount. NO cutting or drilling is required.

Our Standard Duty Rubber edge ships with the complete hardware set to install the rubber on the plow.

Our Standard Duty Rubber edge will last longer, wear better than the Deere rubber edge.

What are the benefits of upgrading your 54” or 60” Deere Front Mounted Plow to our Standard Duty Rubber Plow Edge Kit?

Stops the abrasion and surface damage to the pavement.

Ends the plow banging when lowered and every time it strikes a raised pavement edge.

Greatly reduces the plow blade “tripping” which makes plowing easier and safer

Allows snow to be pushed onto the lawn areas and grass areas*

You can push snow over irrigation heads, control valves and other irrigation parts buried in the lawn*

No more rust on the driveway or garage floor from the plow blade edge.

Allows the plow to be used for spring and fall clean up including moving leaf piles and mulch and even stone.*

Reduces the amount of stone material displaced from plowing on gravel and aggregate driveways when using the rubber edges.*

*Assumes using controlled plow down force and avoid using the plow float feature. The rubber edge requires minimal down pressure to properly clear the pavement and excessive down pressure simply wears the edge more than necessary.

SBS, Filling a Void to make the 54” plow most useful

Deere doesn’t make any other edges for these plows, which is a shame as it limits the use and function of these plows. So I decided to design and produce a range of plow edges for these plows. These options include;

Standard Rubber edges for basic use

Heavy Duty or Commercial Grade rubber edges for heavy use

Extreme Duty Rubber edge which can handle extensive plow use in harsh conditions.

Variations of the UHMW Composite plow edge in single sided, double sided as well as thicknesses of the UHMW which serve a range of needs from residential tasks to heavy commercial use.

Rubber Plow top flap to enhance the plows function and operation.

We even produce versions of the steel edge for those who need of desire to use them.

We have greatly expanded the range of function, uses and tasks for these plows, which benefits their owners.

Please make sure to select the plow edge or kit which best aligns with your needs.

Questions and Answers commonly asked about these Rubber Plow Edges.

Q. 1.- How long should the SBS rubber edges last?*

A. 1.- Assuming they are used properly and our directions are followed, its reasonable to think that the owner should be able to realize the following use experience with these rubber edges. Standard Duty Edges 300 to 400 residential Drives. Heavy Duty Edges should see 500 to 600 residential drives and Extreme Duty edges should be able to plow 800 to 1,000 residential drives. This assumes the residential drive is >300’ in length and 4,000 total sq ft of pavement area. Actual results will vary, these are only guides.

Q. 2.- How long does it take to install these plow edge kits on the Deere 54” and 60” Plows?

A. 1.- Depending upon the plows age and wear condition the plow installation should range from 20 to 30 minutes for new plows to 60 minutes + for plows with extensive wear and rust. Obviously, the skill, tools and work environment will also impact these results.

Q.3.- Should the plow owner use Impact Tools to remove the old plow edge and install the new plow edge?

A.3.- The impact tools can be used to speed up the removal of the old hardware and edge. We also suggest you keep the old hardware with the steel plow edge when removed. However, please be careful using impact tools to install the new edges as the impacts tend to over tighten the hardware. The new rubber edge and UHMW plow strap should not be installed with an impact as its likely to damage the materials by using too much torque to install the hardware.

Q.-4.- What tools are needed to remove the steel plow edge and install the new rubber edges from SBS?

A.-4.- The steel plow edge hardware are metric, so metric sockets will be needed. We sell all of our edges and products with SAE hardware for use of SAE tools. Basically, sockets, ratchet and perhaps combination wrenches.

Q.5.- Any special installation instructions to be aware of?

A. 5.- Our included use and installation instructions provide all details, but to highlight a few important details, Make sure to align the rubber edge so there is 1.75” to 2” of rubber under the plow blade. Make sure to use a tape measure to the rubber edge is level across the plow face. Also make sure to lubricate hardware before installing and removing it. Follow the speciic torque guidelines provided for hardware.

Q. 6.- Any other “words of experience” new owners should be aware of when switching from a steel plow blade to a rubber plow edge?

A. 6.- There are several. Clean the plow blade once the steel edge is removed. If there is any paint missing or rust areas, make sure to touch up those areas. You may want to wax or apply a paint sealer to the plow moldboard to protect it long term. Be careful with the steel plow edge as they are sharp from grinding on the pavement and often heavier than people expect. And make sure to paint the 54” plow steel strap if using it on the new edge so the bottom of the steel strap isn’t rusty and damages the new plow rubber.

Q. 7.- What are the mistakes new rubber edge plow operators make most often?

A.7.- They use excessive plow down pressure. They use the plow “float” feature like its a requirement when in reality, it often is disruptive. They don’t adjust the plow shoes as described. They scrape too hard with the plow rubber edge, which is too much down pressure. They also think the rubber will scrape off ice and hard pack snow, which it won’t at first. If you have ice or hard pack snow, apply a little snow melt to the area, wait 10 minutes and clear it again. The pavement will be clean and clear.

Q.8.- Any closing thoughts?

A. 8.- Make sure to properly adjust the steel plow shoes on the plow so they are not touching the pavement when the rubber edge is being used. Raise the plow shoes so the bottom of the shoes is level with the bottom of the plows steel moldboard, or about 2” above the driveway surface. You can also flip the shoes over and install them upside down in the plow mounts so the shoes are with the plow but can’t be used to disrupt the plows function. Call us if you have any questions or need help with machine operation. Usually the solutions are easy to implement.

*Assumes using controlled plow down force and avoid using the plow float feature. The rubber edge requires minimal down pressure to properly clear the pavement and excessive down pressure simply wears the edge more than necessary.

Important Notes about these products

Stainless Steel hardware Installation and Use Tips

Avoid using impact tools on stainless steel hardware as the speed of the tool builds heat in the hardware finish.

This heat can cause “galling” of the hardware which can result in the hardware “cold welding” itself, which you want to avoid.

Always lubricate hardware before installation and prior to its removal with a silicone of other appropriate lubricant.

Please use proper torque settings as outlined in the instructions.

Please avoid over tightening the hardware as it distorts the edges and can damage the UHMW edge mounting straps.

Impact tool use can also damage the square holes in the mounting straps by “pounding” on them, making the holes has less holding strength.

Always install all of the hardware finger tight and make sure the edges are in place and properly squared to the plow edge before tightening.

We suggest always tightening our plow edge hardware with the center bolt first, then one bolt right of center, then one left of center. Continue this alternating until all bolts are properly tightened. Using this method results in a smooth and properly flush rubber edges and mounting straps.

Thank you for your interest in our products and please do not hesitate to contact us with any questions or concerns you may have.

This kit includes FREE shipping, via USPS or UPS Ground Delivery in the Lower 48 States

Custom made to fit the Deere 54” front Snow Plow, this edge replaces the steel edge on the plow with our Standard Duty plow rubber edge. The rubber edge will protect your pavement from the surface abrasion and scraping damage from the steel edge which comes on the plow when purchased new.

How to order this product

54 Inch Deere Front Plow

Decide whether you want to order the Standard Duty Rubber Edge Only or the Standard Duty Rubber Edge Kit.

If you have a 54” Deere plow and have the steel strap edge on the plow, you can order just the rubber edge and it will ship with a complete set of corrosion resistant hardware. As long as you have the 54” plow steel plow strap, you can save some money and use that strap on the 54” plow new rubber plow edge.

If you prefer all new components, or your steel plow strap is missing or damaged, order the Standard Duty Rubber Edge KIT for everything you need to install this on your plow and replace the steel plow edge.

Who are the Standard Duty Rubber Plow Edge/ Kit Customers?

Those owners who want to stop the pavement surface abrasion and switch to a rubber edge to protect the pavement surface.

The owner who wants a professionally designed and machined rubber edge kit which will bolt directly onto the plow and provide years of reliable use.

Those owners who don’t want a project where they have to modify and alter materials to make them fit.

Those owners who want to stop the plow banging on the pavement and the steel plow edge striking pavement expansion joints, etc.

Those owners who are tired of tearing up the yard and lawn or grass areas with the steel plow edge.

If your plow blade “trips” often while plowing, our rubber edge will dramatically reduce these plow tripping events by allowing the plow to clear the raised sections and edges more easily.

Contents of the Standard Duty Plow Edges and the Standard Duty Plow Edge Kits for the 54” and 60” Deere front plows

Deere 54” Front Plow

The Standard Duty Rubber Plow Edge includes

(1) 4” x 1/2” fully machined rubber edge

Full Set of corrosion resistant hardware set to install the new rubber edges

The Standard Duty Rubber Plow Edge KIT includes

(1) 4” x 1/2” fully machined rubber edge

the custom made UHMW Mounting strap to secure the rubber edges..

Full Set of corrosion resistant hardware set to install the new rubber edges

Our Rubber Edge Kit is the parts and pieces to transition the plow from its steel edge to the rubber edge kit.

Center Cut Holes or Top Edge Cut Holes

on the 54” Plow Rubber Edge

Mounting holes are available along the top edge of the 54” rubber edge or down the center of the 54” rubber edge. Here is the difference and the advantages of either option.

Center Cut Holes in the 54” edge requires the use of our UHMW mounting strap to install this on your plow.

Center Cut Holes are for the rubber edges sold in our Center Cut 54” Rubber Plow edge Kits. By machining the mounting holes down the center of the 4” tall rubber edge, our UHMW mounting strap and hardware provide you with a “Double Sided Wear Edge” for the standard rubber edge.

Benefits of ordering the center cut holes includes

Ability to have two wear edges on the rubber material. Each side would have 1.25” of rubber edge beneath the plow blade.

When the rubber edge wears on one side, flip the rubber edge over and start with the other wear side.

Provides a total of 2.5” of rubber wear out of the edge, using 1.25” of rubber on each side of the edge.

Having 1.25” of the 1/2” standard duty rubber edge makes the rubber flexible enough to protect the pavement from abrasion, but the rubber edge is still stiff enough to scrape snow from the surface which might be hard packed from being driven over.

Please note, in order to use the 54” rubber edge with the holes down the center, you MUST order our 54” rubber Plow edge KIT which includes our UHMW mounting strap machined to mount the edge and our hardware package to install the rubber edge and the UHMW strap on your plow.

The steel plow edge on the 54” Deere can NOT be used for the Center Cut rubber plow edge as the steel strap is too wide to mount the rubber with the holes down the center of the rubber edge.

Top Edge Hole Location on the 54” Deere Plow Rubber Edge.

You can select our rubber plow edge for the 54’ Plow with the mounting holes along the top edge of the rubber. You can use the 54” plow steel strap to mount the 54” Standard Duty Rubber Edge with the holes cut into the rubber along the top edge. This rubber edge can also be installed as part of our “Kit” with the Standard Duty Rubber Edge and the UHMW Mounting kit and hardware.

Advantages of ordering the 54” Rubber Plow Edge with holes cut into the rubber along the top edge of the rubber include;

The standard duty rubber edge can be installed with the steel plow edge strap (following specific installation instructions) which might be on your plow.

Using the top cut hole location makes the rubber edge amount below the steel strap about 2.5” with about 2” of that distance below the bottom of the plow.

Standard Duty Rubber Edge

or

Standard Duty Rubber Edge Kit

We offer the “Rubber Only” and the “Rubber Edge Kit”.

The “Rubber Only” is intended to be a replacement rubber edge for those who have been using our rubber edge kit and need to replace it. Please do NOT order the Rubber ONLY option with the center cut holes if you do not have our UHMW mounting strap kit. The rubber edge can not be mounted using the steel strap when the holes are cut down the center as the steel strap does not provide the clearance for holes with

The “Rubber Edge Kits” are for those owners who are removing the plows steel edge and desire to upgrade their plow to a professionally machined rubber edge plow kit on the market.

How our Rubber edge is Superior to the Deere rubber edge sold under part number M42868

The Deere rubber squeegee sold under M42868 is 3” tall and just under 1/2” thick.

Our Standard rubber squeegee is 4” tall, 1/2” thick and weighs 34% more than the Deere rubber edge

Our Standard Rubber edge ships with either center cut or top edge cut holes already in the rubber and ready to mount. NO cutting or drilling is required.

Our Standard Duty Rubber edge ships with the complete hardware set to install the rubber on the plow.

Our Standard Duty Rubber edge will last longer, wear better than the Deere rubber edge.

What are the benefits of upgrading your 54” or 60” Deere Front Mounted Plow to our Standard Duty Rubber Plow Edge Kit?

Stops the abrasion and surface damage to the pavement.

Ends the plow banging when lowered and every time it strikes a raised pavement edge.

Greatly reduces the plow blade “tripping” which makes plowing easier and safer

Allows snow to be pushed onto the lawn areas and grass areas*

You can push snow over irrigation heads, control valves and other irrigation parts buried in the lawn*

No more rust on the driveway or garage floor from the plow blade edge.

Allows the plow to be used for spring and fall clean up including moving leaf piles and mulch and even stone.*

Reduces the amount of stone material displaced from plowing on gravel and aggregate driveways when using the rubber edges.*

*Assumes using controlled plow down force and avoid using the plow float feature. The rubber edge requires minimal down pressure to properly clear the pavement and excessive down pressure simply wears the edge more than necessary.

SBS, Filling a Void to make the 54” plow most useful

Deere doesn’t make any other edges for these plows, which is a shame as it limits the use and function of these plows. So I decided to design and produce a range of plow edges for these plows. These options include;

Standard Rubber edges for basic use

Heavy Duty or Commercial Grade rubber edges for heavy use

Extreme Duty Rubber edge which can handle extensive plow use in harsh conditions.

Variations of the UHMW Composite plow edge in single sided, double sided as well as thicknesses of the UHMW which serve a range of needs from residential tasks to heavy commercial use.

Rubber Plow top flap to enhance the plows function and operation.

We even produce versions of the steel edge for those who need of desire to use them.

We have greatly expanded the range of function, uses and tasks for these plows, which benefits their owners.

Please make sure to select the plow edge or kit which best aligns with your needs.

Questions and Answers commonly asked about these Rubber Plow Edges.

Q. 1.- How long should the SBS rubber edges last?*

A. 1.- Assuming they are used properly and our directions are followed, its reasonable to think that the owner should be able to realize the following use experience with these rubber edges. Standard Duty Edges 300 to 400 residential Drives. Heavy Duty Edges should see 500 to 600 residential drives and Extreme Duty edges should be able to plow 800 to 1,000 residential drives. This assumes the residential drive is >300’ in length and 4,000 total sq ft of pavement area. Actual results will vary, these are only guides.

Q. 2.- How long does it take to install these plow edge kits on the Deere 54” and 60” Plows?

A. 1.- Depending upon the plows age and wear condition the plow installation should range from 20 to 30 minutes for new plows to 60 minutes + for plows with extensive wear and rust. Obviously, the skill, tools and work environment will also impact these results.

Q.3.- Should the plow owner use Impact Tools to remove the old plow edge and install the new plow edge?

A.3.- The impact tools can be used to speed up the removal of the old hardware and edge. We also suggest you keep the old hardware with the steel plow edge when removed. However, please be careful using impact tools to install the new edges as the impacts tend to over tighten the hardware. The new rubber edge and UHMW plow strap should not be installed with an impact as its likely to damage the materials by using too much torque to install the hardware.

Q.-4.- What tools are needed to remove the steel plow edge and install the new rubber edges from SBS?

A.-4.- The steel plow edge hardware are metric, so metric sockets will be needed. We sell all of our edges and products with SAE hardware for use of SAE tools. Basically, sockets, ratchet and perhaps combination wrenches.

Q.5.- Any special installation instructions to be aware of?

A. 5.- Our included use and installation instructions provide all details, but to highlight a few important details, Make sure to align the rubber edge so there is 1.75” to 2” of rubber under the plow blade. Make sure to use a tape measure to the rubber edge is level across the plow face. Also make sure to lubricate hardware before installing and removing it. Follow the speciic torque guidelines provided for hardware.

Q. 6.- Any other “words of experience” new owners should be aware of when switching from a steel plow blade to a rubber plow edge?

A. 6.- There are several. Clean the plow blade once the steel edge is removed. If there is any paint missing or rust areas, make sure to touch up those areas. You may want to wax or apply a paint sealer to the plow moldboard to protect it long term. Be careful with the steel plow edge as they are sharp from grinding on the pavement and often heavier than people expect. And make sure to paint the 54” plow steel strap if using it on the new edge so the bottom of the steel strap isn’t rusty and damages the new plow rubber.

Q. 7.- What are the mistakes new rubber edge plow operators make most often?

A.7.- They use excessive plow down pressure. They use the plow “float” feature like its a requirement when in reality, it often is disruptive. They don’t adjust the plow shoes as described. They scrape too hard with the plow rubber edge, which is too much down pressure. They also think the rubber will scrape off ice and hard pack snow, which it won’t at first. If you have ice or hard pack snow, apply a little snow melt to the area, wait 10 minutes and clear it again. The pavement will be clean and clear.

Q.8.- Any closing thoughts?

A. 8.- Make sure to properly adjust the steel plow shoes on the plow so they are not touching the pavement when the rubber edge is being used. Raise the plow shoes so the bottom of the shoes is level with the bottom of the plows steel moldboard, or about 2” above the driveway surface. You can also flip the shoes over and install them upside down in the plow mounts so the shoes are with the plow but can’t be used to disrupt the plows function. Call us if you have any questions or need help with machine operation. Usually the solutions are easy to implement.

*Assumes using controlled plow down force and avoid using the plow float feature. The rubber edge requires minimal down pressure to properly clear the pavement and excessive down pressure simply wears the edge more than necessary.

Important Notes about these products

Stainless Steel hardware Installation and Use Tips

Avoid using impact tools on stainless steel hardware as the speed of the tool builds heat in the hardware finish.

This heat can cause “galling” of the hardware which can result in the hardware “cold welding” itself, which you want to avoid.

Always lubricate hardware before installation and prior to its removal with a silicone of other appropriate lubricant.

Please use proper torque settings as outlined in the instructions.

Please avoid over tightening the hardware as it distorts the edges and can damage the UHMW edge mounting straps.

Impact tool use can also damage the square holes in the mounting straps by “pounding” on them, making the holes has less holding strength.

Always install all of the hardware finger tight and make sure the edges are in place and properly squared to the plow edge before tightening.

We suggest always tightening our plow edge hardware with the center bolt first, then one bolt right of center, then one left of center. Continue this alternating until all bolts are properly tightened. Using this method results in a smooth and properly flush rubber edges and mounting straps.

Thank you for your interest in our products and please do not hesitate to contact us with any questions or concerns you may have.

While our plan is to inventory all of these items for next winters product demand, in the meantime, we will be producing these and building inventory of our kits. This can result in a delay of up to 14 business days to ship your order. We will keep you posted on the status. Please make sure to follow the use and installation instructions for best results. Please see our installation instructions for more details.